Pharmacies, whether independent, chain, hospital-affiliated, or embedded in other clinical settings, face relentless pressure to deliver accuracy, safety, and efficiency. Rising patient expectations, complex medication regimens, and regulatory scrutiny only amplify these demands. In this environment, the practice of medical kitting - assembling pre-defined sets of medications and supplies for specific patient needs or procedures - transforms from a convenience into a competitive necessity.

The Nuance of Pharmaceutical Kitting

Kitting within pharmacies is more than just bagging together items on a shelf. At its core, pharmaceutical kitting involves systematically grouping medicines and related items according to protocols tailored for particular conditions or treatment pathways. This can range from routine antibiotic starter packs to highly specialized oncology regimens requiring precise sequencing.

The scope widens when you consider hospital kitting for surgical suites, laboratory kitting for diagnostic workflows, and veterinary kitting where animal health needs mirror human complexity. Even cannabis kitting gains traction as dispensaries strive for consistent dosing and compliance.

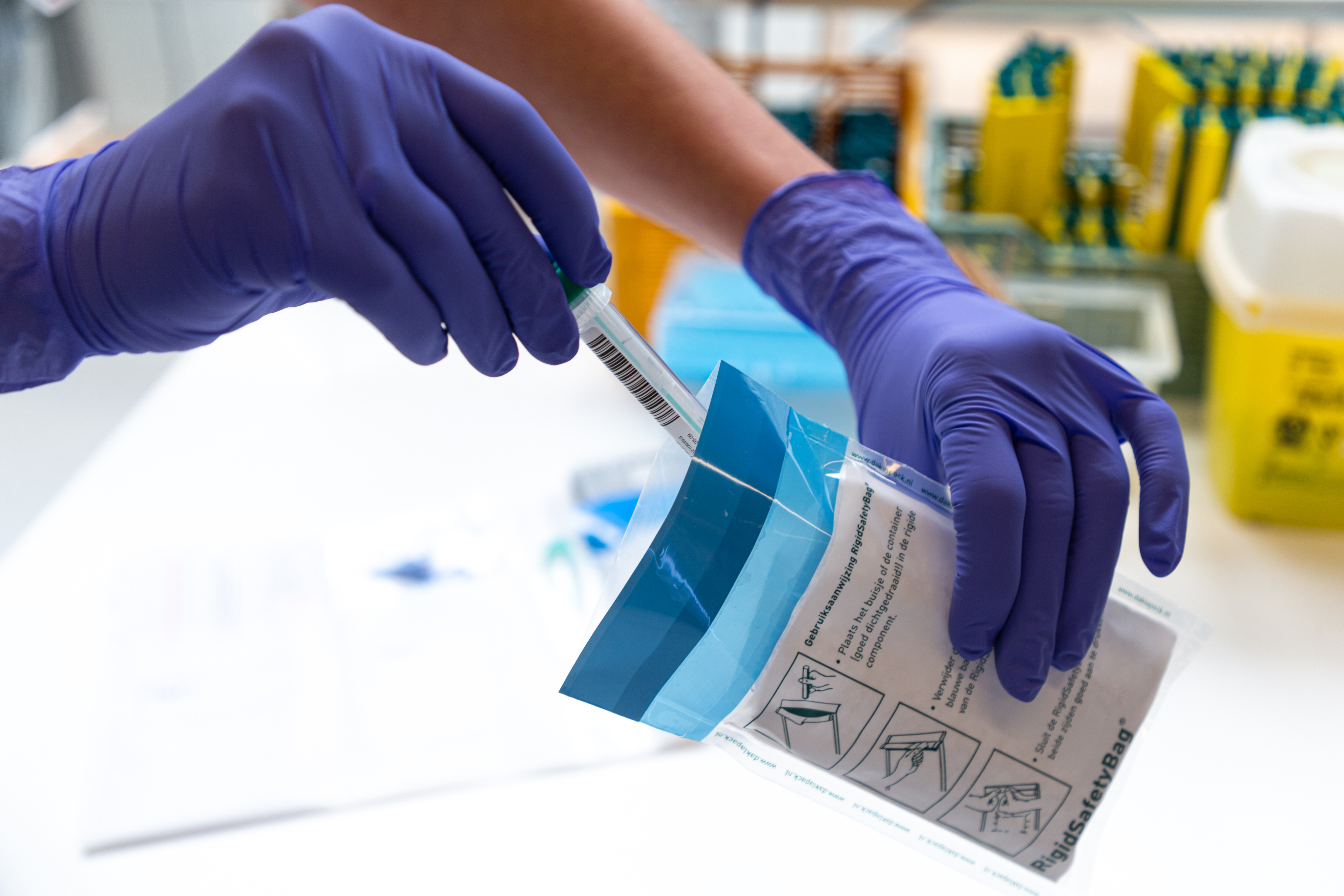

Experience shows that truly effective pharmacy kitting hinges on understanding both the clinical context and operational realities. For instance, oral chemotherapy kits must account not only for drug interactions but also patient education leaflets and disposal bags for hazardous waste. Any gap in assembly can ripple through patient outcomes and regulatory audits alike.

Why Kitting Matters in Modern Pharmacy Operations

Time is rarely on the pharmacist’s side. Dispensing errors still rank among the most common causes of adverse events in healthcare. When every second counts - especially during high-traffic hours - advanced kitting strategies become a lifeline.

Consider an outpatient pharmacy servicing 600 scripts daily: manual item-by-item picking leads to bottlenecks at check-out and increases risk of error as staff fatigue sets in. By contrast, implementing well-designed pharmacy kits for chronic conditions such as hypertension or diabetes can shave minutes off each fill while supporting therapy adherence through inclusion of reminders or blood glucose logs.

Beyond efficiency, consistent kitting also supports compliance with Good Manufacturing Practice (GMP) standards as well as local regulations mandating clear labeling and traceability. Logistics providers specializing in pharmaceutical distribution now routinely offer custom kitting services for government authorities managing vaccination drives or emergency response stockpiles.

Anatomy of a High-Performing Kit

No two pharmacies have identical workflows or patient populations. That said, successful kits share certain characteristics: they are purpose-built for end-user needs; assembled under strict quality controls; updated regularly based on clinician feedback; and traceable from sourcing through delivery.

Take the example of dental care kitting: one regional chain developed distinct kits for pediatric versus geriatric patients undergoing prophylaxis visits. Each kit included not just age-appropriate fluoride varnishes but also relevant consent forms in multiple languages after noticing high rates of incomplete documentation among non-English-speaking families.

Hospital pharmacies often go further by customizing anesthesia kits down to provider preference: some anesthesiologists request specific brands or sizes of syringes based on hand size or tactile feedback during intubation procedures. Getting these details right means fewer delays mid-procedure - a win both clinically and operationally.

Technology’s Role: Barcoding to Robotics

Manual assembly works up to a point but falters at scale or complexity. That’s where technology enters decisively.

Barcoding systems now allow technicians to scan each component before sealing a kit. This step reduces human error by flagging any missing or mismatched item instantly rather than days later when inventory discrepancies surface. Advanced setups integrate directly with pharmacy management DaklaPack US copacking software so that replenishment orders trigger automatically once kit stock falls below threshold levels.

Larger operations are introducing robotics into their assembly lines. I saw firsthand how a Midwest medical logistics provider leveraged semi-automated conveyors to assemble over 5,000 IV compounding kits per week during flu season peaks without sacrificing accuracy. Human oversight remained essential for final checks but robotics handled repetitive portioning with unmatched speed.

Cloud-based platforms bring another layer by enabling real-time tracking across multiple sites - invaluable when supplying nursing home products to dozens of facilities spread across rural counties with variable demand patterns week-to-week.

Edge Cases: When One Size Does Not Fit All

Even mature kitting programs encounter friction points that require judgment calls:

A specialty pharmacy handling biotech drugs faced an issue when temperature-sensitive monoclonal antibodies arrived too early at clinics lacking adequate refrigeration space over weekends. The solution? Time-release insulated packaging paired with dynamic routing software that adjusted delivery schedules based on weather and facility readiness instead of rigid weekly drop-offs.

In another instance, veterinary clinics requested customizable supplement kitting because dog breeds have widely varying weight bands affecting dose calculations - what worked smoothly for Labradors would overdose a Chihuahua if staff relied solely on pre-filled packets designed around averages. Here, flexible batch runs replaced static inventory models until usage data justified new standardized options.

Cannabis & CBD kitting introduces regulatory minefields around childproof packaging and state-specific labeling requirements that change quarterly if not monthly. Staying compliant demands ongoing collaboration between legal teams and supply chain managers rather than set-it-and-forget-it templates.

Inventory Optimization Through Data

The best-run pharmacies lean heavily on data analytics to refine their kitting strategies continuously. Usage trends expose which combinations see rapid turnover versus those languishing unsold on shelves - information that guides kit redesigns or prompts promotional campaigns targeting slow-moving therapies such as niche sports nutrition formulations or superfoods blends popular among weekend warriors but less so among elderly patients managing chronic disease diets.

I recall one supermarket-based pharmacy adjusting its ready meals & meal kits after discovering via POS data that soup & broth mixes outsold pasta threefold during winter months yet reversed come springtime when salad dressings surged alongside allergy prescriptions.

This level of granularity allows pharmacies to reduce waste while also anticipating surges tied to local events (for example marathon weekends spiking demand for electrolyte beverage kits). It pays dividends at both the bottom line and community reputation levels when shelves never run bare nor overflow with expired goods destined for disposal fees.

Trade-Offs: Standardization Versus Customization

Every pharmacy grapples with the tension between standardizing kits for simplicity versus customizing them for unique clientele or prescriber preferences:

Standardized approaches streamline training and minimize packing errors but may lack flexibility needed by specialty clinics treating rare diseases whose protocols evolve rapidly alongside research advances. Customization wins loyalty among prescribers who value tailored solutions yet risks ballooning SKUs beyond manageable levels unless monitored closely. Ultimately most find balance through modular designs: base kits covering core components plus add-on modules addressing site-specific nuances (such as extra PPE during COVID flare-ups). Veteran pharmacists quickly learn that rigidity breeds frustration while unchecked customization erodes operational discipline - wisdom learned through missed deliveries or costly rework following miscommunication between front-line staff and procurement teams. Here is a brief comparison table summarizing key trade-offs:

| Approach | Pros | Cons | |------------------|--------------------------------------|-------------------------------------------| | Standardized | Efficient training; lower error rate | Less adaptable; potential clinician pushback| | Customized | Prescriber satisfaction; clinical fit| Higher costs; logistical complexity | | Modular | Some flexibility; controlled variety | Requires careful planning |

Regulatory Compliance: An Unforgiving Landscape

Few industries operate under stricter scrutiny than pharmaceuticals. Every aspect of pharmacies’ operations falls under local boards of pharmacy regulations as well as federal oversight (think FDA rules in the US).

Medical logistics providers specializing in hospital pharmacy support know that even minor lapses can trigger costly recalls or fines - sometimes running five figures per infraction if labeling fails GMP muster after periodic audits. For subscription box kitting models selling supplements online direct-to-consumer (D2C), compliance headaches multiply given varying ingredient disclosure requirements across state lines. Diagnostic system suppliers assembling COVID test kits faced whiplash early in the pandemic as guidance shifted almost monthly regarding swab specifications and result reporting protocols. One practical tip: Keep documentation detailed yet accessible so auditors spend less time digging through records during spot checks. Especially when dealing with chemicals kitting or industrial colorants used by affiliated hospital labs, robust chain-of-custody protocols protect against accidental contamination claims later traced back to upstream assembly slip-ups rather than true product failures. For cannabis dispensaries offering curated CBD bundles alongside traditional retail items like tea kitting or sweeteners meant to mask taste profiles, compliance extends into point-of-sale signage down to font size mandates imposed by local ordinances. No matter your niche within pharmacy operations, invest early in regulatory expertise before scaling up volume-driven processes lest expensive retrofits eat into already slim margins later on.

Real-World Impact: A Case from Practice

At one urban teaching hospital’s outpatient arm serving 9,000 patients monthly across diverse demographics, leadership undertook an overhaul of existing medication adherence programs using advanced kit design principles:

Pharmacists began collaborating directly with case managers who tracked readmission rates post-discharge among heart failure cohorts. After piloting three versions over six months (varying informational inserts plus inclusion/exclusion of blood pressure monitors), they settled on a hybrid model blending standardized drug assortments with optional support tools tailored per language preference. Within nine months readmission rates dropped by nearly 12 percent compared to historical baselines - savings easily justified additional up-front labor spent refining kit content based on granular patient follow-up surveys. The lesson? Meticulously designed pharmaceutical kitting pays off tangibly at both population health metrics and individual care moments if frontline teams remain empowered to iterate rather than slavishly follow top-down directives divorced from everyday realities. The project team attributed success not just to what was included but what was intentionally left out after testing revealed certain paperwork overwhelmed older adults who preferred phone follow-up instead. That kind of ground-level insight cannot be gleaned from spreadsheets alone; it comes from deep engagement with both patients’ lived experiences and clinicians’ workflow frustrations alike.

Implementing Advanced Kitting: Practical Steps

Getting started need not mean massive investment overnight nor wholesale change disrupting current operations all at once. Here are five practical steps drawn from experience optimizing multiple settings:

Map current workflows by shadowing pharmacists during high-volume periods; note bottlenecks ripe for improvement via pre-assembled kits. Engage front-line staff when designing initial prototypes since their buy-in accelerates adoption far more effectively than mandates from above. Pilot small batches first using barcoding tools wherever possible before scaling up automation investments such as conveyors or robotic arms. Track performance rigorously post-rollout using concrete metrics such as fill times per script line item error rates kit utilization ratios relative to forecasted demand spikes (e.g., flu season surges). Document everything meticulously including rationale behind changes so future audits proceed smoothly even years down the road amid inevitable staff turnover cycles.A disciplined rollout trumps hasty attempts at perfection every time - especially when adapting lessons learned from adjacent sectors like food supplements manufacturing where shelf-life constraints force nimble inventory rotation practices applicable equally well within OTC medication inventory management domains.

Beyond Medications: Expanding Kitting Horizons

While most attention focuses rightly on prescription drugs themselves modern pharmacies increasingly extend advanced kitting concepts into adjacent categories:

Personal care bundles combining skincare products liquid hand soap hair coloring products appeal powerfully within beauty-focused retail settings seeking upsell opportunities without overwhelming display cases; Household cleaning product assortments bundled seasonally help drive repeat traffic while smoothing out revenue volatility tied tightly otherwise just to insurance reimbursement cycles; Retailers leveraging ecommerce webshop platforms have seen strong uptake among D2C customers ordering subscription box formats featuring everything from nuts & dried fruits snack packs through full meal prep ingredient boxes; Even plant fertilizers animal feed agricultural seeds find their way into curated “starter packs” sold via affiliated garden centers sharing warehouse space with large multi-use pharmacy distribution hubs; The lesson here? Once foundational processes stabilize around pharmaceutical items themselves there exists huge upside extending proven techniques outward into lifestyle-oriented verticals previously considered outside core business boundaries.

Final Thoughts: Continuous Improvement Is Non-Negotiable

Pharmacy operations never stand still long enough for any single strategy - even advanced medical logistics providers’ gold standards - to remain optimal indefinitely. Stay curious about emerging technologies whether robotics cloud-based track-and-trace blockchain-powered chain-of-custody verification tools; Listen harder still to front-line feedback filtering out noise yet acting decisively upon recurring pain points surfacing repeatedly regardless location size specialization; Above all reward experimentation tempered by rigorous measurement not mere gut instinct alone because even seasoned experts occasionally miss blind spots only revealed after boots hit shop floor cement day after day shift after shift; Optimizing pharmacies through advanced kitting strategies remains less about magic bullets more about cultivating cultures where process improvement takes root organically yielding benefits felt everywhere from boardroom dashboards straight through bedside counseling moments changing lives one carefully packed kit at a time.